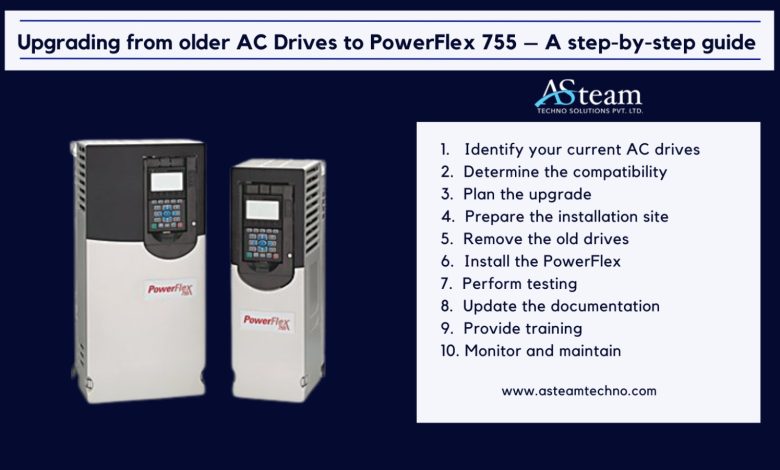

How to Upgrade older AC Drives to PowerFlex 755 – A step-by-step guide

If you want to enhance performance, reduce downtime, and increase efficiency in your industrial processes, PowerFlex 755 drives are the ideal replacement for conventional AC drives. Listed below is a step-by-step guide for performing the upgrade:

1. Identify your current AC drives:

The first step is to determine which AC drivers your system is currently utilizing. You can use this to find out if they work with PowerFlex 755 drives and what kind of system modifications could be required.

Being an AI language model, I don’t have access to your specific industrial equipment. To identify your current AC drives, you may frequently find the nameplate or label on the drives themselves. This label should include the name of the maker, the model number, and any technical information like the voltage and power rating. You can contact the manufacturer or consult the system literature for further information about your current AC drives.

2. Determine the compatibility:

Find out the AC drives you presently own, and then check to see if they are compatible with the PowerFlex 755 drives. Contact the manufacturer or the PowerFlex 755 user guide for confirmation of compatibility.

To determine whether your current AC drives are compatible with PowerFlex 755 drives, consult the product manuals for each device. Various AC motor combinations and motor types can normally be used with the PowerFlex 755 drives.

Read: Rockwell Automation 20G11NC015JA0NNNNN 755 AC Packaged Drive

3. Plan the upgrade:

Create a budget, resource, and timetable strategy for the update. Don’t forget to account for any system modifications that could be necessary.

- To decide the upgrade’s scope, specify the precise drives or systems you wish to update and the goals you hope to achieve. Consider concepts like dependability, efficacy, and performance.

- Build a project plan: Make a complete update plan with a budget, resources, and due dates. Make a list of any potential risks or challenges and develop backup plans to address them.

4. Prepare the installation site:

Make sure the installation site is prepared by examining the power requirements, cooling system, and environmental factors.

- Verify the power source: Check to see if the PowerFlex 755 drives can be powered by the power source. Ensure that the voltage and current specifications meet the needs of the drive.

- Install electrical grounding: A suitable grounding is necessary for the drives to operate safely and reliably. Install grounding as per the manufacturer’s instructions.

5. Remove the old drives

After being detached from the power supply, the old drives need to be uninstalled from the system. Make careful you lock out the power source as part of your safety precautions.

- unplug power: Always remove power from the drives and any attached devices before removing any drives to ensure that the system is secure enough to operate on.

- Spend some time labelling each cord and connector to the old drives. This will make it easier to install the new drives and ensure that every connection is made properly.

6. Install the PowerFlex 755 drives:

Follow the manufacturer’s instructions for installing the Rockwell Automation PowerFlex 755 drives. It could be necessary to wire, code, and setup the new drives.

- Check the installation location: Be sure to follow the manufacturer’s instructions and suggestions when preparing the installation site.

- Check for compatibility: As per the manufacturer’s instructions, ensure that the installation location has been properly prepared.Make that the PowerFlex 755 drives are compatible with your system and appropriate for the motor and load being controlled.

- After installing the mounting hardware according to the manufacturer’s instructions, prepare the mounting surface.

- Consolidate the drives: Use the included hardware to fasten the PowerFlex 755 drives after carefully positioning them on the mounting surface.

7. Perform testing:

After installation, check the PowerFlex 755 drives to make sure they are functioning properly. This entails running diagnostics, checking for errors, and making sure the motor is working properly.

- Set up the drive parameters in line with any special needs of your system and the manufacturer’s instructions.

- Test your power-up: Make that the drives switch on and work as planned by connecting the system to a power source.

- System evaluation: To make sure the drives are handling the motor and load correctly, test the system. Look for any anomalies or issues with the system.

8. Update the documentation:

Be sure to update all documentation, including system schematics, wiring diagrams, and operating manuals, to reflect the changes occurred during the upgrade.

9. Provide training:

Provide the relevant staff with training on how to operate, maintain, and troubleshoot the new drives.

Determine the necessary training: Establish the specific training needs for the personnel who will be handling the drives. Technical know-how, adherence to safety protocols, and troubleshooting skills could be required for this.

- Create a training plan: Make a training plan that specifies the topics to be addressed, the training structure, and the training resources needed.

- Organise training sessions: Set up staff training sessions, either in-person or via online training resources. These sessions should cover the characteristics and capabilities of the PowerFlex 755 drives, as well as how to set them up, utilize them, and troubleshoot common issues.

10. Monitor and maintain:

Regularly check and maintain the PowerFlex 755 drives to keep them performing at their best.

By following these steps, you can successfully replace obsolete AC drives in your industrial operations with PowerFlex 755 drives. Keep safety, planning, and testing as your top priorities at all times to ensure a successful update.

Advantages of Upgrading older AC Drives to PowerFlex 755

Performance, functionality, and dependability are all enhanced and improved when upgrading previous AC drives to PowerFlex 755. Rockwell Automation produces the PowerFlex 755 drive system, a reliable and feature-rich drive system built to withstand the challenges of contemporary industrial applications.

1. Enhanced Motor Control:

The PowerFlex 755 AC drive’s enhanced motor control is a standout feature, providing cutting-edge features that optimise motor performance and raise industrial applications’ general efficiency. The PowerFlex 755 offers accurate speed and torque control through the use of advanced control algorithms and features, which has a number of advantages. By precisely adjusting motor speed, acceleration, and deceleration with improved motor control, operators may increase production efficiency while assuring optimal performance for a variety of processes and applications. Due to the drive’s sophisticated control capabilities, accurate torque control is also possible, improving precision and responsiveness in difficult operations. Hence, this degree of management improves the system’s capacity to manage varying loads, assuring dependable performance even in changeable operating environments.

2. Expanded Communication Options:

Expanded communication possibilities are available with the PowerFlex 755 AC drive, offering high levels of flexibility and integration capabilities for industrial applications. The PowerFlex 755 supports a number of communication protocols, including DeviceNet, ControlNet, and EtherNet/IP, enabling easy integration with current automation systems. With real-time data sharing, remote monitoring, and centralised control made possible by this improved communication capabilities, the system as a whole may function more efficiently and with better coordination. While, the drive can readily integrate into Ethernet-based networks by using EtherNet/IP, providing strong and dependable connectivity with other systems and devices. With DeviceNet compatibility, a variety of industrial devices, sensors, and actuators may connect quickly and easily. High-speed and deterministic communication is made possible via ControlNet support, making it perfect for applications that call for exact synchronisation and coordination.

3. Advanced Diagnostics and Troubleshooting:

The PowerFlex 755 includes built-in fault logging capabilities and diagnostic tools. These tools help reduce downtime, increase maintenance efficiency, and swiftly detect and fix problems. The drive offers thorough details regarding defects and alarms, enabling proactive troubleshooting and lowering the possibility of unanticipated failures.

4. Safety Features:

The PowerFlex 755 places a high priority on safety and adherence to regulations. Safe Torque Off (STO) and Safe Speed Monitor (SSM), among other integrated safety features, are available. By ensuring that the drive continues to function securely in unusual circumstances or crises, these safety measures assist avert potentially dangerous situations. Moreover, Upgrade to PowerFlex 755 to safeguard priceless equipment and improve operator safety.

5. Scalability and Flexibility:

Numerous motor sizes and applications may be accommodated with the PowerFlex 755. It offers a wide range of power ratings, giving you the freedom to adjust to various system needs. This scalability makes it simple to integrate into current installations and makes it possible for further expansions or alterations.

A Comprehensive Guide On Computer Science Assignment

6. Energy Efficiency:

Energy savings are possible with the upgrade to PowerFlex 755. The drive includes energy-saving technologies including regenerative braking, adaptive motor control algorithms, and energy monitoring capabilities. Over time, these features assist save money by lowering energy use and supporting ecological programmes.

In conclusion, upgrading traditional AC drives to PowerFlex 755 offers a number of benefits, including greater motor control, more communication choices, cutting-edge diagnostics, improved safety features, scalability, and energy economy. These advantages help industrial applications operate more productively, with less downtime, better system dependability, and lower costs.

When you need to Upgrade older AC Drives to PowerFlex 755, Asteam Techno Solutions Pvt Ltd is here to help you. With an inventory of obsolete and surplus spare parts and a team of qualified engineers, there’s no breakdown or fault we cannot solve. Wherever you are in the world, Asteam Techno Solutions Pvt Ltd is the best Industrial Automation parts supplier and solutions provider in India as well as globally. Get support for all types of equipment from AC, DC and servo drives through to PLCs, HMIs and other automation parts.